In industrial production, commercial operation, and public facilities, electric motors are the core power equipment, and their energy consumption accounts for a very high proportion of the total electricity consumption. According to industry statistics, the power consumption of motors in the global industrial sector accounts for over 60% of the total industrial electricity consumption, and in China, this proportion exceeds 65%, with some high energy consuming areas even reaching 80%. Against the backdrop of intensified energy price fluctuations and the promotion of the "dual carbon" target, efficient motors have become a key path to breaking energy cost pressures and optimizing energy consumption structures, thanks to their efficient conversion ability of electrical energy.

1���、The core impact of energy efficiency difference: the dilemma of energy waste in ordinary motors

The energy efficiency level of a motor directly determines the efficiency of converting electrical energy into mechanical energy, and the energy efficiency difference between ordinary motors and high-efficiency motors often means significant hidden energy waste. According to the current motor energy efficiency standards, the efficiency range of ordinary motors (usually corresponding to level 3 energy efficiency) is mostly concentrated in 75% -89%, while the efficiency of high-efficiency motors (level 2 energy efficiency and above) generally exceeds 90%, and ultra high efficiency motors with level 1 energy efficiency can reach over 94%.

This seemingly limited efficiency gap will translate into significant energy consumption differences during long-term high load operation. Taking the commonly used 45kW three-phase asynchronous motor in industrial scenarios as an example, assuming its annual operating time is 8000 hours, the electricity price is calculated at 0.8 yuan/kWh:

If a regular motor with an efficiency of 86% is used, the annual power consumption is approximately (45kW × 8000h) ÷ 86% ≈ 418605 kWh, and the annual electricity bill expenditure is approximately 418605 × 0.8 ≈ 334884 yuan;

If replaced with a high-efficiency motor with an efficiency of 94%, the annual power consumption will decrease to (45kW × 8000h) ÷ 94% ≈ 382979 kWh, and the annual electricity bill expenditure will be approximately 382979 × 0.8 ≈ 306383 yuan;

Only increasing energy efficiency by 8 percentage points can save about 28501 yuan in electricity bills annually, equivalent to nearly 10 months of operating costs for a regular motor. If the motor power is greater and the operating time is longer, the energy cost saved will increase exponentially.

In addition, ordinary motors have lower energy efficiency and generate more thermal energy loss during operation, which not only wastes electrical energy, but also may cause excessive temperature rise of the motor, accelerate internal component aging, indirectly increase equipment maintenance frequency and cost, and form a vicious cycle of "high energy consumption, complex maintenance, and increased cost".

2、Full lifecycle perspective: cost advantage reconstruction of efficient motors

Some users' concerns about high-efficiency motors are mainly due to their relatively high initial procurement costs. However, from the perspective of the entire lifecycle of the equipment (usually 10-15 years), the total cost advantage of high-efficiency motors is extremely obvious, and the difference in initial investment can be quickly compensated for through short-term electricity cost savings.

Taking a 22kW motor as an example, the market price for a regular motor is about 3000-3500 yuan, while the price for a high-efficiency motor is about 4500-5500 yuan. The initial purchase price difference is about 1500-2000 yuan. Based on the previous calculations, the high-efficiency motor with this power can save about 3000 yuan in electricity bills per year. Even if calculated based on the highest initial price difference of 2000 yuan, it only takes 8 months to recover the additional investment. During the entire 10-year usage cycle, high-efficiency motors can save a cumulative electricity cost of 300000 yuan, which is more than 60 times the initial procurement cost, and the cost advantage far exceeds that of ordinary motors.

At the same time, the design and manufacturing process of high-efficiency motors are more advanced, and the losses of stator and rotor iron cores, winding copper, etc. are significantly reduced. The stability during operation is higher, the temperature rise is lower, and it can effectively reduce problems such as bearing wear and insulation aging. The maintenance cycle is usually extended by more than 50% compared to ordinary motors, and the annual maintenance cost can be reduced by about 2000-5000 yuan (depending on the motor power). From the perspective of the entire chain of "procurement operation maintenance", the comprehensive cost advantage of high-efficiency motors is irreplaceable.

3、Policy support and selection strategy: maximizing the energy-saving value of high-efficiency motors

In order to promote the popularization and application of efficient motors, multiple support policies have been introduced at the national and local levels to further lower the application threshold for enterprises. At the national level, high-efficiency motors have been included in the "Government Procurement List of Energy saving Products", and government agencies are required to prioritize the selection of high-efficiency motors for procurement; Meanwhile, eligible high-efficiency motor promotion projects can apply for energy-saving subsidies, with the subsidy ratio usually ranging from 10% to 20% of the equipment unit price. At the local level, some provinces have included the transformation of high-efficiency motors in the "Energy Conservation and Carbon Reduction Special Action", providing tax exemptions (such as "three exemptions and three reductions" for corporate income tax) or one-time rewards to transform enterprises, further shortening the investment return cycle.

When choosing high-efficiency motors, enterprises need to develop scientific selection strategies based on their own energy consumption scenarios to maximize energy-saving value

1. Precise matching of load characteristics: Select the motor power based on the actual load rate of the equipment to avoid the phenomenon of "big horse pulling small car" - if the load rate is consistently below 60%, a low-power high-efficiency motor or a frequency converter can be selected to reduce ineffective energy consumption; If the load rate remains above 80% for a long time, priority should be given to selecting level 1 energy-efficient motors to ensure energy-saving effects under high loads.

2. Pay attention to energy efficiency levels and protection performance: prioritize choosing level 1 energy efficiency motors (efficiency ≥ 94%), whose long-term energy-saving benefits are much higher than level 2 energy efficiency motors; At the same time, choose the appropriate protection level according to the usage environment (such as IP54 or above for dusty environments and IP55 or above for humid environments), to avoid motor efficiency degradation or failure caused by environmental factors.

3. Selection of operating modes: For equipment that operates continuously (for more than 12 hours per day), it is important to focus on the long-term stability and efficiency of the motor, and prioritize the selection of high-efficiency permanent magnet synchronous motors (with an efficiency 3% -5% higher than asynchronous high-efficiency motors); For equipment that operates intermittently or starts frequently, high-efficiency motors with excellent starting performance can be selected to reduce energy loss during the starting process.

In the current era where energy costs have become one of the core operating costs for enterprises, high-efficiency motors are not only "energy-saving equipment", but also a strategic choice for enterprises to reduce costs and increase efficiency, and achieve green transformation. It can directly reduce electricity bills through significant energy efficiency advantages; Reduce comprehensive operation and maintenance costs through longer maintenance cycles; In addition, with the support of policy dividends, a cost optimization model of "short-term cost recovery and long-term returns" has been formed. For enterprises pursuing sustainable development, the comprehensive promotion and application of high-efficiency motors is not only a refined control of energy costs, but also a forward-looking investment in future competitiveness, and an important practice to help achieve the "dual carbon" goal.

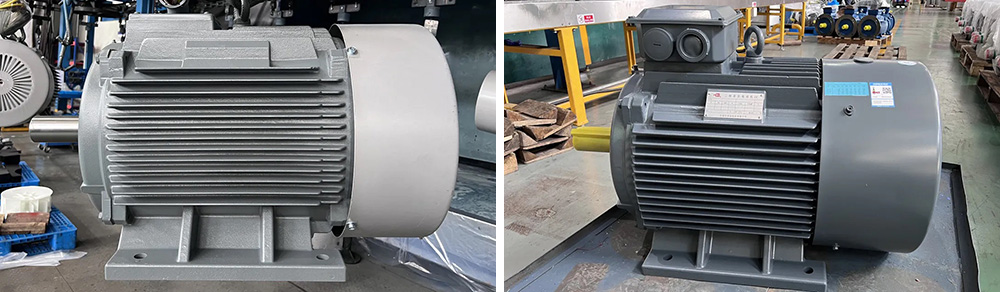

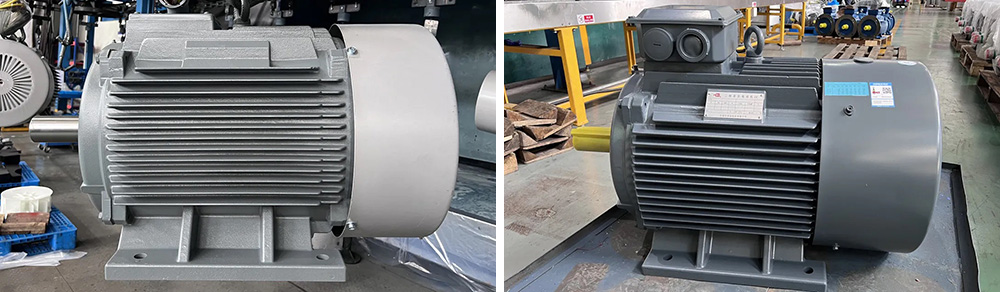

Hengda Electric has always been dedicated to the research and development, production, and service of efficient motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.